- Description

- Technical specifications

- Main characteristics Strong points of the machine

- Use / Examples

- Documents / Downloads

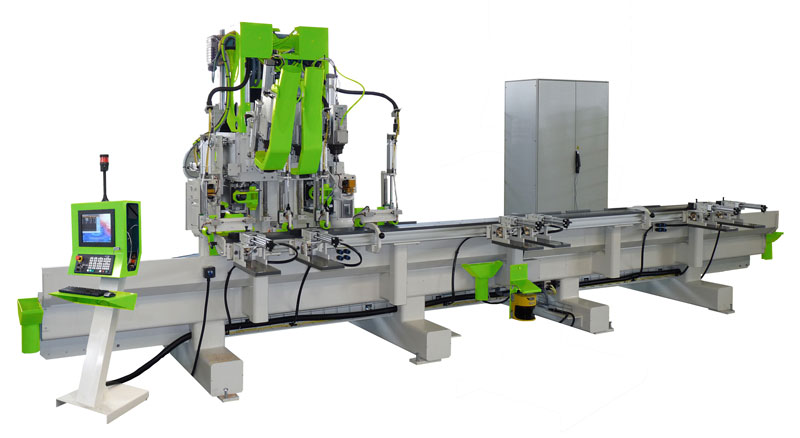

Numerically controlled machining centres for Wooden Parts

Material

- Wood

Applications

- Automatic centre specially designed for working long, narrow wooden parts

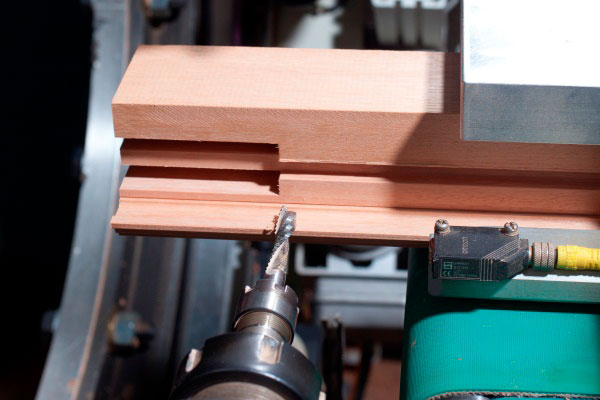

- Cutting, drilling, grooving

Allowable part dimensions:

- Maximum section 150 x 150 mm

- 3,000 mm as standard / up to 7,000 mm as option

- Feed rate 100 m/min

- Numerically controlled centre for work on parts in Wood and derivatives

- Allows the production of cuts, drillings and grooves on the top, bottom, rear and end of the parts

- Modular construction, work in 3 axes, option to adapt the number of carriages and spindles for a large variety of cuts

- Machine equipped with one or more moving rear carriages, and a carriage above it that machines the part held on the fixed working surface

- Manual or automatic parts feed with indexing working surface,

- Exclusive clamping equipment not needing any manual adjustment,

- Varied applications: street furniture, wooden buildings, verandas, fitting out, varied long narrow parts

- High accuracy +/- 0.2 mm per linear metre

- Automatic programming post-processor with batch file and or 2/3D model import as option